Complete Industrial Engine Buying Guide: What to Know Before You Invest

Selection of the correct industrial engine is the key to your business. The engine is what makes a machine work well, save money, and last a long time. This is true for construction machines, heavy equipment, or factory machines. This industrial engine buying guide will help you understand what to look for before buying a strong, heavy-duty engine.

Why Choosing the Right Industrial Engine Matters

Your machinery is supported by an industrial engine that keeps the operations on the appropriate course. Making a wrong engine selection may cause problems. The right engine ensures:

- Consistent Performance: Works with difficult loads and hard work.

- Lower Costs: Cuts on fuel and maintenance costs.

- Reliability: Reliable engines such as 4tnvengine have been found to offer good performance.

- Environmental Compliance: Meets emission requirements.

- Safety: Properly matched engines reduce overheating and operational dangers.

Finding the precise engine will save time, reduce cost & work pressure and make your work easy and secure.

Key Factors to Consider Before Buying an Industrial Engine

There are several factors that should be looked at before buying:

- Power Requirements: Make positive the engine has enough strength in your system.

- Operating Environment: If your machine works in dust, water, warmth, or cold, the engine may want greater protection like filters or rust-proof elements.

- Maintenance and Support: Engines want ordinary care. Check if spare components, service facilities, and a guarantee are available.

- Efficiency and Fuel Consumption: Engines that use much less gasoline save cost ultimately.

- Brand Reputation: Choose a dependent brand for higher excellence and guidance.

- Compliance with Regulations: Make positive the engine follows local safety and pollutants guidelines.

Checking these things helps the engine last longer and reduces problems.

Engine Fuel Type

Fuel type affects cost, performance and maintenance:

- Diesel Engines: Strong, long lasting and good for heavy duty work.

- Gasoline Engines: Lighter and quieter, but uses more fuel. Good for small machines.

- Natural Gas Engines: Cleaner, cheaper in some areas, and better for the environment.

Choosing the right fuel engine depends on your machine, fuel availability and running costs. Top engine brands like 4TNV Engines offer options for different fuels engines, helping you choose the best engine for your needs.

Buying New vs Used Industrial Engines

| Factor | New Industrial Engine | Used Industrial Engine |

| Price | Higher upfront cost | Lower upfront cost |

| Performance | Peak efficiency | May be reduced |

| Warranty | Full manufacturer coverage | Limited or none |

| Maintenance | Minimal early | May require frequent upkeep |

| Reliability | High | Depends on prior usage |

| Parts Availability | Easy | Sometimes limited |

| Compliance | Meets latest standards | May not meet new regulations |

| Best For | Long-term heavy use | Budget or short-term needs |

New Trends in Industrial Engines

High performance and modern industrial engines are built to boost productivity, save time, and support sustainability.

- Hybrid and Electric Engines: In some cases, manufacturers are manufacturing hybrid or electric engines to reduce fuel consumption and produce less pollution.

- Better Fuel Efficiency: New engines will consume less fuel with the same power.

- Smart Monitoring: Sensors and smart technology can be used to monitor engine performance, alert when problems arise, and prevent breakdowns.

- Low-Emission Engines: Engines are currently produced so that they do not create as much pollution and that they conform to strict rules by the environment.

When you stay informed, your work become more efficient, environmentally friendly, and aligned with modern standards

Top 6 Mistakes to Avoid Before Buying an Industrial Engine

Buying the wrong industrial engine for your business can take more time and money. Here are the most common mistakes and the way to avoid them:

Ignoring Machine Compatibility

Not all engines are made for every work, each engine is made with specific features designed for a particular type of work. Using an engine that doesn’t fit your equipment can cause terrible performance, common breakdowns, or maybe harm. Always test your device’s specifications and select an engine that fits perfectly.

Focusing Only On Price

The price might be enticing and at the same time it may spell bigger issues in the future. Less expensive engines can either wear out quicker, consume more fuel or need more maintenance. It is not only the initial cost that needs to be considered, but also the expenses in the long-term.

Overlooking Reputable Brands

Brands that are trusted have been found to be reliable and of high support. Using a brand that is not well known can lead to the inability to find spare parts or technical support. When investing in a well-known brand, they give you quality and a guarantee.

Skipping Warranty or Technical Support Checks

The warranty will cover you in case of a fault in the engine, or a premature failure. Technical services are assisting in the troubleshooting and maintenance. Avoiding these checks may make you pay expensive repairs.

Ignoring Fuel Efficiency

Engines that use too much fuel increase your running costs. Fuel-efficient engines save money and are better for the environment. Always check fuel usage before you buy.

Skipping Inspection for Used Engines

The used engines are cheap, but there might be some undetectable issues. The latter should be carefully checked to identify leaks, wear and maintenance history. Skipping inspection can lead to unexpected failures.

Avoiding these mistakes ensures your industrial engine is reliable, efficient, and powerful.

Conclusion

In this blog we have mentioned an industrial engine buying guide, what you need to know before buying industrial engines like power, fuel efficiency, maintenance and new trends. For engines that work well, save money, and last a long time, choosing a trusted engine like 4TNV Engine is a smart choice that gives you a guarantee to make sure the engine works well and fits your needs.

FAQs

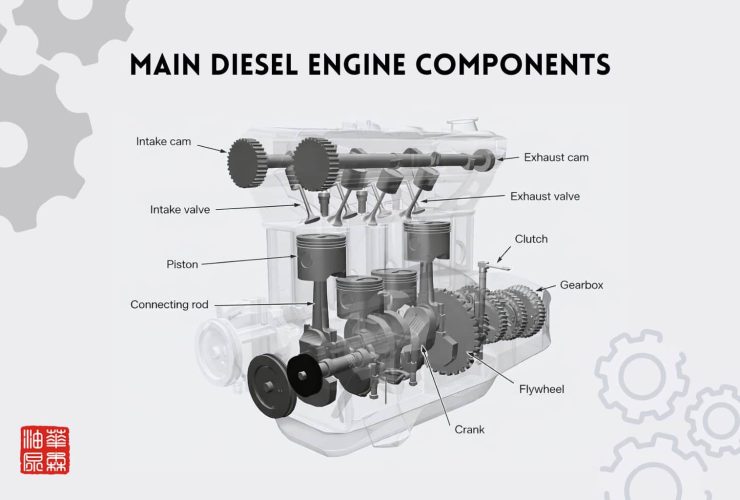

Q1: What are Industrial Engines?

A: Industrial engines are machines that give power to run other machines. They are used in factories, farms, and construction. They are strong and made to work for a long time.

Q2: Should I purchase a new or used commercial engine?

A: Both engines are more reliable and come with guarantees and guides. Used engines can save money for light or short-term work, as long as you check them carefully.

Q3: Which fuel kind is satisfactory for business engines?

A: Diesel is commonly used in heavy and continuous tapping.

Q4: How do I keep my industrial engine?

A: Perform ordinary oil and clear out changes, display cooling and exhaust structures, and use diagnostic gear or sensors to discover anomalies early.

Q5: What is the longevity of an industrial engine?

A:The lifespan depends on how much the engine is used and how well it’s taken care of. Good diesel engines can last 10–15 years or more with proper maintenance.